Forward Looking Acoustic and Infrared Imaging Technologies

Applications

🔧 Compressed-Air Leak Detection

Leaks in compressed-air systems generate high-frequency turbulence that are invisible to the naked ear—but the A2’s sensitive microphone array picks them up instantly, enabling rapid detection of even the smallest faults in pipelines.

🌀 Vacuum System Leak Detection

Vacuum leaks emit very subtle sounds that are often inaudible, yet the A2 acoustic camera captures these faint signals with precision—allowing quick localization without needing contact or risking damage to equipment.

⚙️ Loose-Joint Vibration Detection

When a screw or joint loosens during operation, it emits high-frequency vibrations. The A2 detects these abnormal sounds in real time and visualizes the exact source—making it possible to fix issues without shutting down machinery.

🚗 Tire-Air Leak Detection

No need for soap or manual checks—the A2 instantly visualizes tiny leaks in tires, pointing out the exact location so you can address the issue quickly and efficiently.

Sound Pressure Level Measurement

By overlaying acoustic imagery with live dB-level readings, the A2 can locate and diagnose a variety of industrial sound sources. This integration of visuals and metrics enhances the intuitiveness, efficiency, and safety of inspections

Other Applications

Gas cylinder gas leak detection / Gas pipeline leak detection / Natural gas pipeline leak detection / Pressurized gas leak / etection / Loose bolts on transmission towers / Loose screws on hoppers / Strange equipment noise detection / Car window sealing check / Compressed Air Leak Detection / Vacuum Leak Identification / Fastener Looseness Checks / Seal Integrity Verification

What is an Acoustic Imaging Camera?

While human hearing is limited to 20 Hz–20 kHz, many hidden faults—like gas leaks, bearing wear, and electrical discharge—emit ultrasonic frequencies above 20 kHz, which are inaudible and undetectable with conventional stethoscopes or microphones.

The FLaiTek A2 acoustic camera, equipped with a 64‑MEMS mic array and a 2–100 kHz detection range, captures both audible and ultrasonic sounds—revealing compressed air and vacuum leaks, loose component vibrations, tire-pressure loss, and more

How does an acoustic camera work?

-

Microphone Array: Simultaneously captures sound signals from multiple sources to enhance spatial accuracy.

-

Beamforming Algorithm: Focuses on sound sources from specific directions, filtering out environmental noise.

-

Acoustic Image Overlay: Displays sound source locations as a heatmap over the image.

-

Low-Latency Rendering Engine: Enables near-instant response, ideal for continuous inspection scenarios.

Boost your industrial diagnostics with the FOTRIC TD2 Acoustic Imaging Camera—engineered for precision leak detection and sound source localization.

Key Features:

-

🔊 64 MEMS Digital Microphones for pinpoint acoustic imaging across 2–100kHz

-

📸 13MP Visual Camera overlays sound data for intuitive diagnostics

-

🧠 Dynamic Noise Reduction Algorithms enhance sound source focus

-

📐 Wide Field of View: 66° × 52° for broad coverage

-

📊 dB-Level Sound Pressure Measurement for actionable insights

-

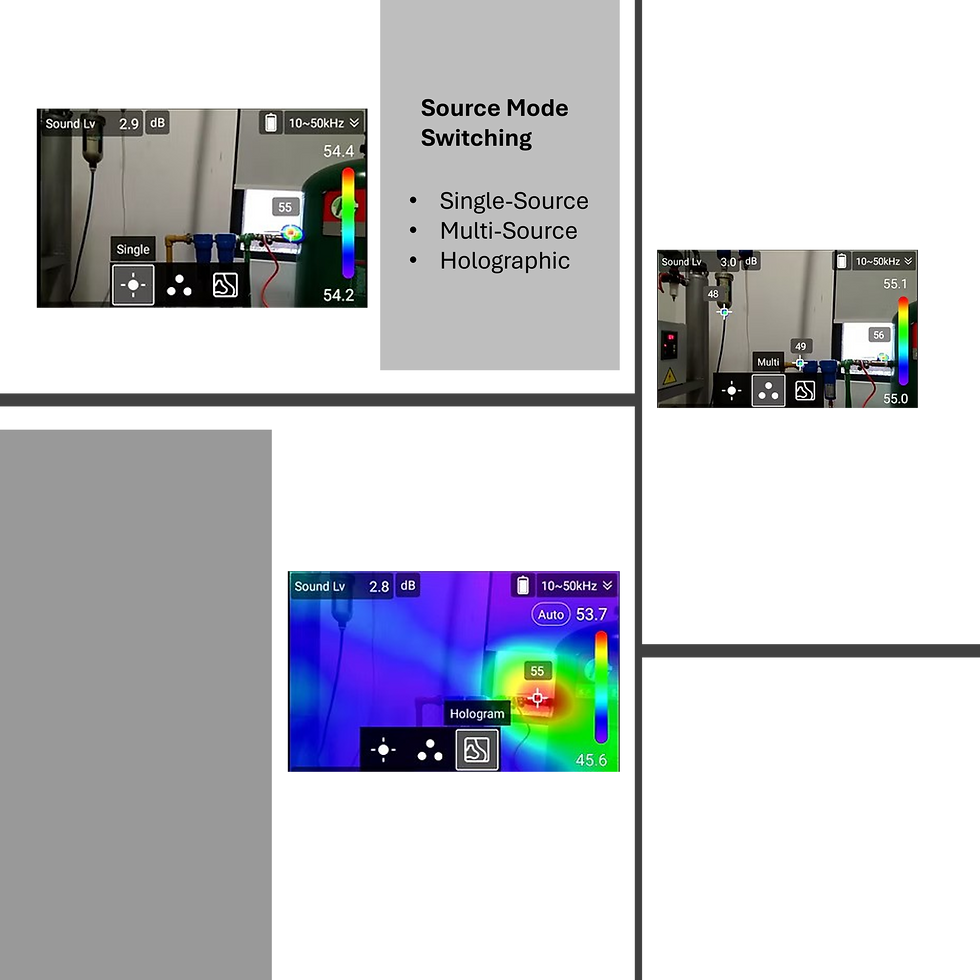

🖥️ 3.5" IPS Touchscreen with Gorilla Glass, supports multi-mode imaging

-

🔋 5000mAh Battery delivers 4+ hours of field-ready operation

-

🧳 Rugged & Portable: IP54 rated, 2m drop-resistant, only 770g

.png)

FLaiTek A2 Acoustic Imaing Camera

Detect compressed air and gas leaks with speed and precision using the FLaiTek A2. This compact, handheld acoustic camera visualizes sound in real time, enabling quick, contactless leak detection—no more relying on soapy water or tedious manual methods. Designed for ease of use in tight spaces, the A2’s intuitive interface and high-sensitivity microphone array help users pinpoint issues with accuracy and confidence. Whether you're in a factory, mechanical room, or high bay area, the A2 makes inspections faster, safer, and more effective—saving both time and energy costs.

.png)

.jpg)

.jpg)